Thermal ratcheting in packed bed thermal energy storage (TES) systems

2025-08-09

Packed bed thermal energy storage systems store sensible heat from a working fluid that can be recovered at a later date. The porous media inside the vessel (typically a low-cost natural rock) provides a high surface area for the working fluid to exchange heat with. These systems are used to integrate low-grade waste heat from industry, and also for recovering "cold" in liquid air energy storage (LAES) systems.

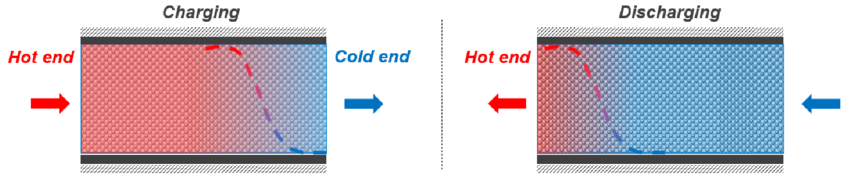

The working principle is best illustrated in an example. Say we have a low-grade waste air stream at 70 °C. The packed bed is currently at 20 °C, and we flow the hot air through the bed. The thermal front will slowly move through the bed, heating up the solid.

Once the thermal front "breaks through" the outlet, we consider the bed to be fully charged. If the vessel is well insulated, the system is considered adiabatic. When a heat source is required, the system is run in reverse with a cold fluid pushing the heat out.

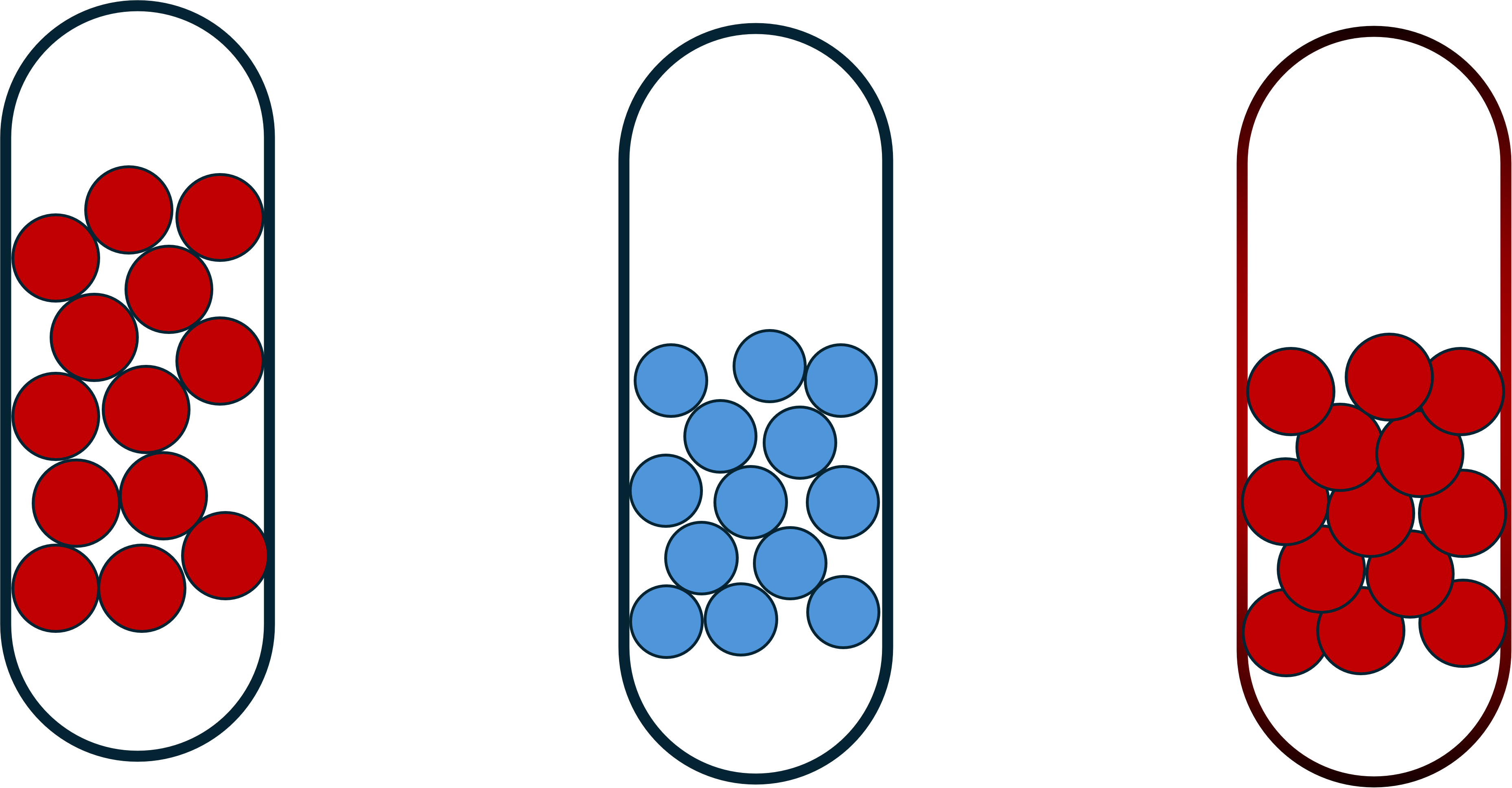

One of the main mechanical design considerations is the issue of thermal ratcheting. Solid media will contract in size as it cools, forming a tighter packing arrangement. When the temperature increases again, the media will try to expand. However, due to the tighter packing arrangement, the media will be constrained, and stresses propagate through the vessel walls. Continuous thermal cycling compounds stresses, and if the thermally induced stresses exceed the yield strength of the tank wall, catastrophic failure would occur.

It is particularly problematic as when the temperature increases, the yield strength of the tank wall typically decreases. Strain gauges on the vessel wall can be used to monitor the wall stress over time.